Though single filters may suffice, optimal filtration is often achieved through the use of several filtration products used in conjunction with one another to create a complete system. Read More…

Our company is the filtering systems expert. We know everything there is to know about filtering liquids and oils for many industries ranging from the petrochemical industry to waste water management. It is our goal to provide customized solutions that you can trust and rely on every day. You will find that our attention to detail and superior service can help you in multiple ways. Contact us to...

At Dynamic Air Inc., we specialize in providing advanced filtration systems designed to meet the diverse needs of industries worldwide. Our team is committed to delivering high-performance products that ensure air quality and system efficiency. We design and manufacture a wide range of filtration solutions, including air filters, dust collectors, and ventilation equipment, tailored to enhance...

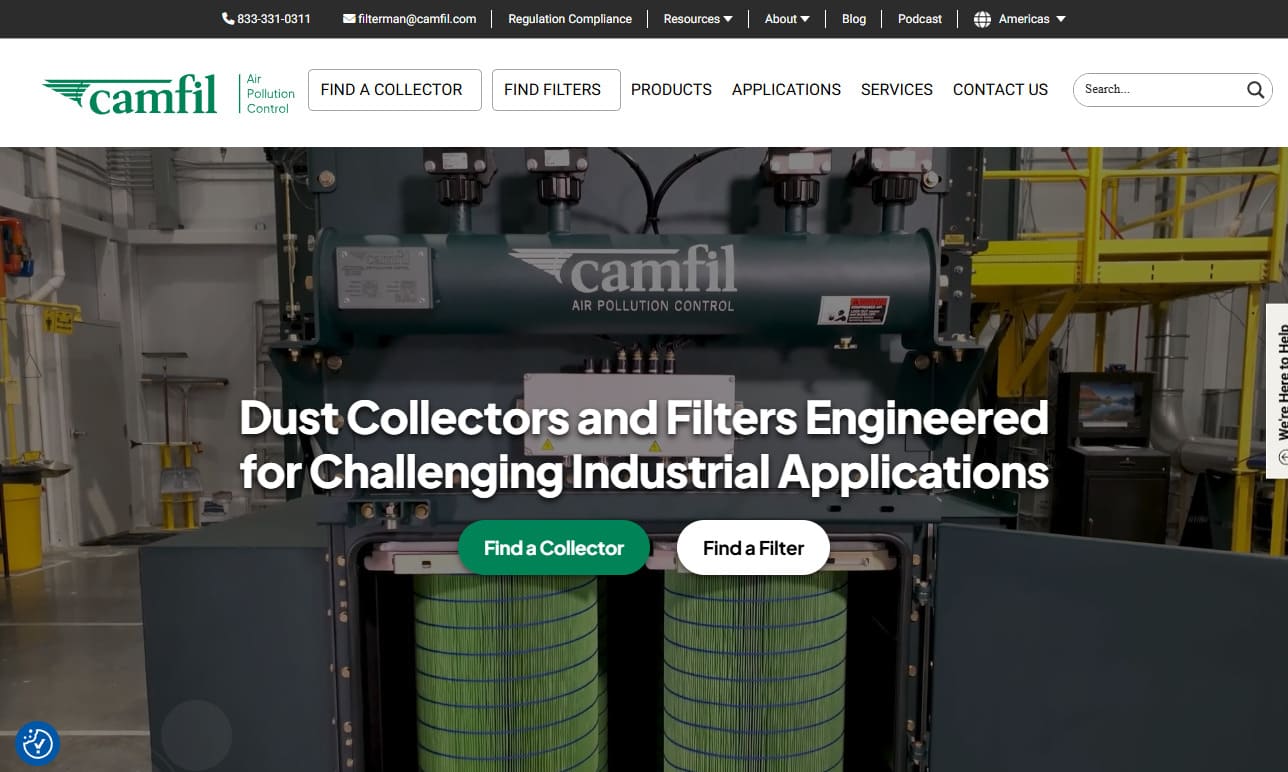

At Camfil APC, we are driven by a commitment to cleaner air and a healthier environment through the design and manufacture of advanced industrial filtration systems. As a global leader in air pollution control, we specialize in developing dust, mist, and fume collection solutions that protect workers, improve manufacturing efficiency, and ensure regulatory compliance.

At All American Air Filters, we take pride in delivering high-performance filtration solutions that protect air quality, extend equipment life, and support healthier environments across industrial, commercial, and institutional settings. Our expertise spans the design and manufacture of advanced air filtration systems engineered to capture contaminants, control particulates, and maintain optimal...

At Freudenberg Filtration Technologies, we dedicate ourselves to advancing air and liquid filtration systems that safeguard people, processes, and the planet. We combine decades of expertise with continual innovation to create solutions that enhance air quality, improve operational efficiency, and protect valuable assets.

More Filtering System Manufacturers

Filtering systems may employ several different techniques or simply the succession of similar but progressively restrictive apparatus. Often incorporated at the point of intake and exhaust as well as inline configurations, these systems promote safety all throughout the manufacturing process. To accommodate complete air or fluid systems, filter media include such varied products as strainers, cartridges, membranes and housings, each of which may be designed to remove large particles from industrial process streams or with the precision to purify water for drinking by removing even microscopic contaminants.

Used to clarify coolants, corrosive chemicals, gasoline, oil, hydraulic fluid, lubricants, water, air intake and exhaust air, filtering systems are easily divided into two major categories: air filters and liquid filters. Despite this division, many of the same techniques are used for each, but with minor adjustments.

Membrane, pressure and vacuum as well as electrically charged filters are among the most commonly used to remove impurities in flow lines for many industries, including food and beverage processing, chemical, pharmaceutical, mining, pulp and paper, automotive and agriculture. Commercial and contexts likewise utilize filtering systems with great frequency in order to promote health and safety for homes, offices and for the environment.

With such variability, there are several important factors to consider when installing a filtration system. The degree of installation must first be considered. Filtration equipment can be portable, mounted or centralized systems, the latter being the most complex. This decision also has a significant impact on the type of filter and collection as it relates to the ease of cleaning or replacing components.

As some filtering systems should run continually, it is important to consider the downtime required for maintenance. The pressure drop or ability to operate through blockages will also impact the frequency of cleaning and repairs. Additional considerations include filtration rate, filter location, stream viscosity and temperature, filter load capacity, maximum flow and absorption.

The particular type of filter will determine many of these variables as will the material used in its construction. Housing and filters may be constructed of aluminum, steel, stainless steel, steel, carbon, sand, durable plastics, Teflon, nylon and other synthetic fibers. The particulates themselves should correlate to the specific filter. Both the size and chemical composition should be compatible to ensure product longevity and efficiency.

Regulatory bodies, such as the International Organization for Standardization (ISO), may require certain filters be used in a given application, though many configurations can result in similar competence.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services